OUR ADVANTAGE

-

![]()

To maintain our leading technical edge, our company continues to increase R&D investment in the color sorter field, with a core R&D team composed of experts in optics, computer science, mechanical engineering and other fields, and annual R&D investment accounting for over 15% of revenue. As a precision equipment integrating optics, machinery, electrical and pneumatic systems, we strive for excellence in core components: imported high-resolution CCD cameras are adopted, combined with independently developed optical filter systems, to achieve 0.01mm-level subtle color difference capture, with imaging accuracy 30% higher than industry standards; industrial-grade high-performance computer chips are equipped, with deeply optimized neural network algorithms implanted, which can process 1000 frames of image data per second in real time, and the response speed of sorting judgment is upgraded to the microsecond level; aviation-grade precision air circuit components are used, which have been verified by 100,000-hour durability tests to ensure zero failure in 500,000 pneumatic operations, with service life 50% longer than traditional components.

The entire system is integrated with AI intelligent cloud platform technology. Through the collaboration of edge computing and cloud big data analysis, dynamic self-optimization of sorting parameters is realized - the equipment can automatically adjust the recognition threshold according to changes in material characteristics, so that the sorting efficiency gradually improves with operating time, reaching a maximum net sorting rate of 99.99%. At the same time, it supports remote online upgrade function, allowing users to obtain the latest algorithms and functional modules without stopping the machine, ensuring that the equipment always maintains cutting-edge performance in the industry and meets the ever-upgrading sorting needs.

-

![]()

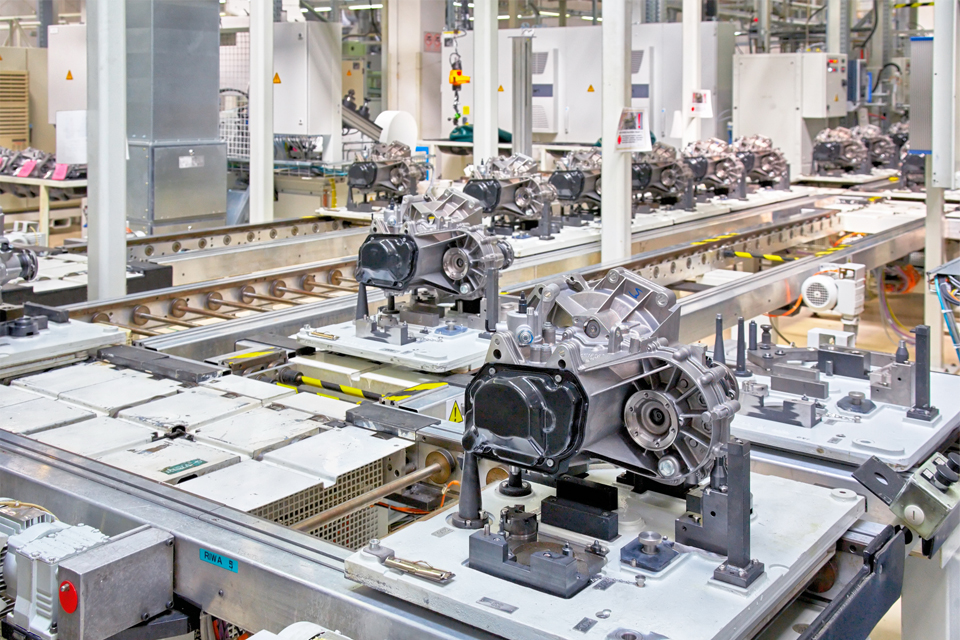

Our company has been deeply rooted in the industry for many years, boasting strong production and technical capabilities. We have a professional R&D team that continuously tackles core technologies, and currently hold more than 30 patents covering key fields such as optical recognition and intelligent algorithms. Relying on the complete industrial chain of the color sorter industry, we possess strong capabilities in upgrading, optimizing and improving color sorters!

Our production workshop is equipped with high-precision processing equipment and adopts automated production lines. It has more than 50 sets of various cutting-edge production equipment and over 30 senior technicians. Coupled with a complete PDM-ERP-MES production management system, we effectively ensure that the products manufactured for customers feature excellent quality and exquisite craftsmanship!